| CONTACT | LOCATION | +386 (0)3 810 41 10 |

Menu

Close

- Products

-

Products

Products

Click on the category text to browse that category!

DISCOVER AND DOWNLOAD OUR NEW CATALOG.

-

- Now in stock

- Price list

- Service

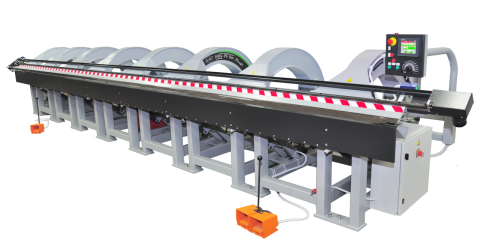

HKS-CNC Profi

HKS-CNC Profi

HKS-CNC Prof is a hydraulic bending machine with motor driven shears, backgauge system, AMS Pathfinder control unit and 1.150mm working depth.

Hydraulic bending machines HKS-CNC Profi are equipped with motor driven shears, backgauge system for moving sheet metal - with a possibility to add a system for automatic setting various sheet metal thicknesses. The bending angle can be automatically adjusted by moving the upper clamp in a horizontal direction. The closing pressure of the upper clamp can be adjusted according to the sheet metal thickness. The CNC software enables the graphic design of profiles of various forms and sizes.

Working width of CNC Profi machine is 1.150 mm, and maximum sheet metal thickness (when bending) is 1,25 mm (steel) and 1,5 mm (Al).

The machines are driven by electric motors through a hydraulic pump, which enables better bending dynamics by means of frequency regulation.

The working lenght of machines are:

- HKS-CNC Profi 8,2m

- HKS-CNC Profi 7m

- HKS-CNC Profi 6,1m

- HKS-CNC Profi 5m

- HKS-CNC Profi 4m

Technical data

|

HKS-CNC Profi 8m |

HKS-CNC Profi 7m |

HKS-CNC Profi 6m |

HKS-CNC Profi 5m |

HKS-CNC Profi 4m |

|

Working length |

8.200 mm | 7.000 mm | 6.100 mm | 5.000 mm | 4.000 mm |

Bending angle |

145° | 145° | 145° | 145° | 145° |

Sheet metal thickness |

Al 1,5 mm, Steel (400 N/mm^2) 1,25 mm |

Al 1,5 mm, Steel (400 N/mm^2) 1,25 mm |

Al 1,5 mm, Steel (400 N/mm^2) 1,25 mm |

Al 1,5 mm,

Steel (400 N/mm^2) 1,25 mm |

Al 1,5 mm,

Steel (400 N/mm^2) 1,25 mm |

Working width |

1.150 mm | 1.150 mm | 1.150 mm | 1.150 mm | 1.150 mm |

Length of machine |

9.300 mm | 8.100 mm | 7.200 mm | 6.100 mm | 5.100 mm |

Weight |

4.400 kg | 4.000 kg | 3.600 kg | 3.100 kg | 2.500 kg |

Number of arms |

8 | 7 | 6 | 5 | 4 |

Power |

5,5 kW |

5,5 kW | 4 kW | 3 kW | 2,2 kW |

Power of electric motor |

5,5 kW | 5,5 kW | 4 kW | 3 kW | 2,2 kW |

|

Cnc ComputerA 17-inch industrial LCD touch-screen makes the programming even more manageable. New shapes of profiles can be programmed by simply entering dimensions and geometry. A profile library enables easy looking up of the saved profiles. CNC Controller which is easy to use with automatic bending-sequence calculation. SmarthPath enables automatic bend sequence programing. Parts are stored in profile library. The number of parts is almost unlimited. You can look up part by name, description or category. |

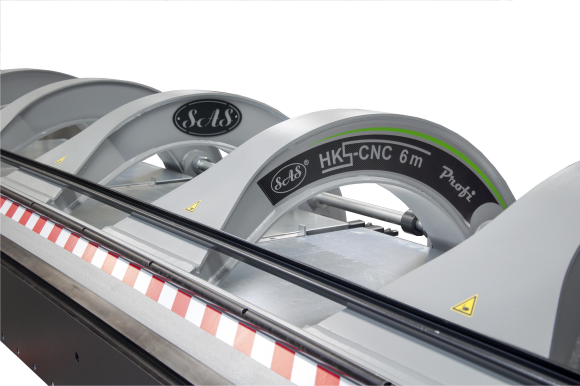

Profi console armsThe Profi console arms are welded and they transfer movement from hydraulic cylinders to the upper clamp, which clamps the sheet metal in place during bending and cutting. The machines are also equipped with a hydraulic movement of the upper clamp which enables adjustments of various sheet metal thickness levels! The closing pressure of the upper clamp is controlled. We therefore press sheet metal with a lower pressure when bending and with a higher pressure when pressing double sheet metal. This increases the operating speed of the machine. |

|

|

|

Backgauge systemThe system of sheet metal movement is electrically driven by front fingers and back support for sheet metal. The position of a backgauge system is measured by a measuring rod. |

Roller shears

Shears s are driven with a hydraulic motor through a steel wire. |

|

Inquiry

Send Inquiry.

To make an inquiry, please fill in the form below and we will contact you in the very near future

Contact

Phone +386 (0)3 810 41 10

Mobile: +386 (0)41 667 473

Fax: +386 (0)3 810 41 11

E-mail: info@strojegradnja-sas.si

Arzenšek Stanko s.p. © Copyrights reserved

Our website uses cookies for better user experience

By continuing to browse our website you agree to our use of cookies which helps us provide you with a good user experience on our website. We use Google Analytics for our own analytical purposes and it installs cookies for this purpose (delete GA cookies). More about cookies.